Charleston Naval Shipyard (CNSY) is situated on 400 acres of hard-land on the Cooper River, approximately five miles north of the historical city of Charleston. It was established in 1901 and became one of the primary maintenance and support facilities for submarines, guided missile ships, destroyers, cruisers, frigates, submarine tenders, and other surface ships.

World War I induced the shipyard to increase production and expand its operations. In March 1917, just before the United States entered the war, Charleston Naval Shipyard had 1,708 civilians on payroll. During the war, the peak employment was 5,600. The work dwindled after the war was over and there was a lot of uncertainty over the future of the yard.

The year 1929 brought the Great Depression to America, but just the opposite to CNSY. The disarmament treaties from WWI stipulated that the US have a minimal number of warships and they had fallen behind. To alleviate this, Congress approved a new cruiser-building program, but needed a place to build and keep them. So, while the rest of the country felt the burden of a depressed economy, CNSY received this boon and its future looked brighter. The dry dock bill passed, and in 1931 funds were appropriated to rebuild the yard's building ways in concrete for destroyer construction. In June 1933 the news reached Charleston that the yard would build a gunboat to be financed by the recently approved National Industrial Recovery Act. President Franklin D. Roosevelt had the new ship named the Charleston in honor of its builders.

The yard benefitted from Public Works Administration (PWA) and Works Progress Administration (WPA) money in the late 1930s. In 1937 The News and Courier would brag that the WPA projects, which had employed an average of 1,200 men a year, had helped make Charleston "the Navy's youngest and fastest growing yard." By 1938 the WPA had spent $895,000 on improvements and the PWA $1,782,800.

A new war threatening in Europe prompted the American Government to increase spending on the military. In 1939, the CNSY had a $3.5 million expansion and improvement program underway employing 1,700 to 1,800 WPA and PWA workers. By the time war was declared, the yard had nearly 2,000 production workers compared to 241 in 1932. The USS Sterrett (DD-407) had been commissioned and was virtually complete; the Roe (DD-418)had been launched and was being fitted out; the Jones (DD-427) and Grayson (DD-435) were on the ways. In addition, the yard had contracts for two more destroyers.

Two of the largest vessels ever built at the yard were two destroyer tenders, the Tidewater (AD-31) and the Bryce Canyon (AD-36). The Keels of these ships were laid in November 1944 and July 1945, respectively. Peak employment of 25,948 was reached in July 1943.

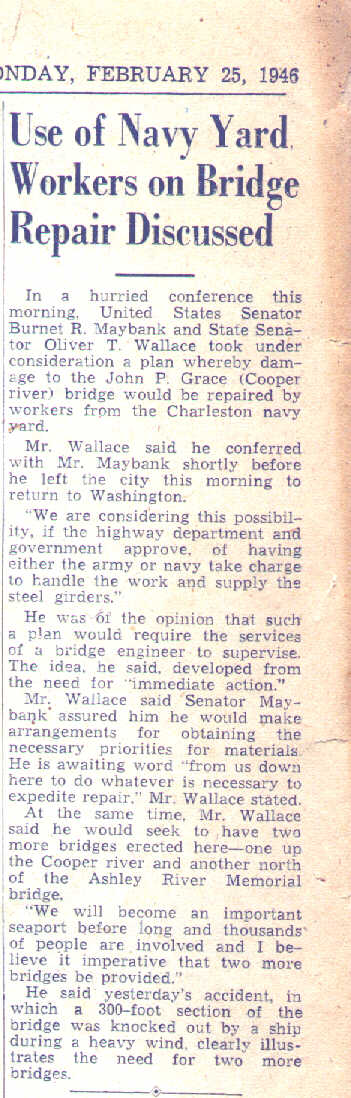

After the war, the shipyard was responsible for the repairs and alterations of captured German submarines. In April 1948 Secretary of the Navy John L. Sullivan told Charleston's Representative Rivers and Senator Burnet R. Maybank that the Navy planned for CNSY to become a submarine overhaul yard and would ask for an initial appropriation for a battery-charging unit.

The first submarine, the Conger (SS-477), arrived for overhaul in August 1948. the shipyard expected to overhaul about 132 ships during the year, and its work force had stabilized to nearly 5,000 persons.

North Korean invasion of South Korea in June 1950 increased production once again. By 1951 the shipyard was back to over 8,000 employees. In all, the shipyard activated forty-four vessels and converted twenty-seven for active fleet duty during the Korean War.

Submarines continued to be built into the 1960s along with missiles, and nuclear submarine overhauls took place like with the Scorpion (SSN-589) in 1962. In 1966 the shipyard completed the first refueling of a nuclear submarine (the Skipjack, SSN-585), and began its first overhaul of an FBM submarine (the Thomas A. Edison, SSBN-610). Work began on deepening Dry Dock No.2 so it could handle the massive FBM submarines and destroyers fitted with sonar.

In 1968 the Navy awarded the first contracts for the 32-ton, 34-foot long, poseidon missile to CNSY. Because of their size, the new missiles had to be assembled in a vertical position, and the construction of a new six-story packaging building became necessary. At about that time, True magazine alleged that there were enough nuclear warheads in Charleston to destroy all the cities in the Soviet Union.

The end of the Vietnam War resulted in a reduction of the workload of the shipyard, but after the closing of the Boston yard, it rebounded. Since then, however, the shipyard has had to close down operations on the complex. On 01 April 1996, operations ceased and it resulted in the loss of 8,722 military and 6,272 civilian jobs.

MORE BASE FACTS

During World War II, the Charleston Navy Shipyard produced 229 ships; 114 of these were built in 1944 alone.

In the 1990s, the Charleston Naval Base was the third-largest in the country, after San Diego and Norfolk, as a home port for afloat forces.

The base was home to nuclear Polaris submarines and was the Navy's principal support facility for the maintenance and resupply of the Navy's sub force during the Cold War.

The base employed 16,000 Navy and Marine Corps personnel and 12,000 civilians in the early 1990s.